The S2 is so far the only continuous flow shot blast machine for the post processing of 3D printed c

The S2 is so far the only continuous flow shot blast machine for the post processing of 3D printed c

Companies across many industries have come to the conclusion that additive manufacturing will make them less dependent on traditional supply chains. However, an essential pre-condition for this approach is that the post processing operations must comply with the requirements for volume production.

Additive manufacturing offers companies the potential to become less dependent on traditional supply chains and, at the same time, make their production operations more flexible and faster. However, the post-processing of 3D printed components is frequently a stumbling block against achieving these goals. On the one hand many post processing steps still require costly manual work, and on the other hand the post processing operations are limited to handling single components or extremely small production lots. This does not allow compliance with the established standards for volume production, namely consistent and repeatable product quality, process control, cost-efficiency and sustainability.

|

|

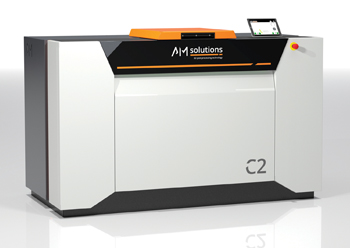

The C2 system allows the fully automatic chemical surface smoothing of plastic components printed from standard polymers and elastomers (including TPU) in series |

AM Solutions – 3D post processing technology, a division of the Rosler group that specialises in the automated post processing of 3D printed components produced in large volumes, now offers new equipment that allows a way out of this dilemma.

SAFE POST PROCESSING

With the new S2 system, AM Solutions – 3D post processing technology offers the so far only continuous flow shot blast machine for post processing of 3D printed plastic components produced with powder-bed printing systems. The Atex compliant plug-and-play machine was designed for round-the-clock three-shift operation and is equipped with interfaces allowing its integration into interlinked manufacturing lines. The work pieces are loaded into the machine as complete print jobs. The loading takes place either by hand or automatically. Once in the machine, the plastic components are gently passing through a special feed loop belt in single piece flow. The tumbling action of the components ensures that they are equally blasted from all sides so that any residual powder is consistently and completely removed from the component surface. Depending on the utilised blast media, the work piece surface can also be homogenised and/or peened. The machine can be equipped with up to four blast nozzles. The number of blast nozzles, the blast pressure and the transport speed can be individually adapted to the respective work pieces. These process parameters can then be stored in the control panel as individual processing recipes. On average, a print job requires cycle times of 15 to 20 minutes. Depending on the condition of the raw work pieces, the Ra surface roughness readings can be reduced by up to 13 µm.

To ensure that the blast media remains at a consistently high quality, the compact shot blast machine is equipped with an effective blast media cleaning and recycling system. This, in combination with the integrated electronic reporting tool, guarantees repeatability of the blasting results, complete process control and a high cost-efficiency of the post processing operation. A patent application covering the machine and the process is pending.

ECO-FRIENDLY SMOOTHING

|

The versatile wet blast system S1 Wet permits not only the removal of residual powder but also the surface finishing of 3D printed metal components |

The C2, presented as a concept solution, illustrates that AM Solutions - 3D post processing technology has its origins in the development and production of machinery and consumables for volume production. This patent-pending innovation enables fully automatic chemical surface smoothing of 3D printed components made of common polymers and elastomers (including TPU) in series. Thus, the costly single piece handling of the work pieces is completely eliminated for this post processing operation. The bounding box allows the processing of work piece dimensions ranging from 10 x 10 x 10 to 300 x 300 x 300 mm and a wall thickness of at least two millimeters. In addition, the process includes a newly developed, non-hazardous processing media that was specially developed by AM Solutions – 3D post processing technology. This ensures that the surface smoothing operation is not only eco-friendly but that the subsequent waste disposal is not subject to any environmental restrictions and is cost-effective.

The C2 chemical surface smoothing system, for which a patent application is pending, can be retrofitted for applying a color dye on plastic components. The C2 will be commercial available in the first quarter of 2022.

WET BLAST SYSTEM

Wet blasting has been a well-established and efficient surface refinement process for metal or plastic components produced in large volumes. With the S1 Wet system AM Solutions – 3D post processing technology has adapted the benefits of this surface treatment method to the specific requirements of additive manufacturing. The highly flexible S1 blast system can be used for cleaning as well as surface homogenistion and smoothing of a wide array of work pieces. A key feature of this technology is that the blast media and process water are mixed together to create a slurry. Depending on the initial surface roughness of the work pieces, their Ra readings can be significantly reduced. To a certain extent this is even possible on internal surface passages and cavities. Since the water in the slurry creates a protective layer on the components, the process is very gentle. It also prevents media particles from penetrating the surface of components made from plastic and soft metals. Another advantage of the wet process is that it maintains the dimensional integrity and prevents the warping of delicate work pieces with complex shapes and thin walls. Wet blasting also prevents the creation of dust and, therefore, requires no protective ATEX accessories.

Another feature of the compact plug-and-play S1 Wet system is its small footprint. On a space of only 2.6 sq m it offers everything that is required for an efficient and sustainable operation. Integrated into the machine is not only the control panel but also the monitoring of the blasting system to ensure a repeatable process, the air filter unit and the waste water management. The discharged wastewater flows into a settle tank to collect most of the sludge. This sludge-type material can be further de-watered by an optional process water cleaning and recycling system integrated into the S1 machine. This reduces the water consumption and waste disposal costs significantly. Additional equipment options, perfectly adapted to the respective processing tasks, allow the utilisation of the S1 Wet ranging from the manual treatment of single components to the fully automatic processing of complete work piece batches.

SERVICE PARTNER

AM Solutions – Manufacturing service partner specialises, in particular, in services related to additive manufacturing. The range of services covers the entire AM process chain and is also designed to meet the requirements of series production. To this end, the Italian-based company of the Rosler Group covers all phases of the product creation process, from the basic conception and testing of the product idea, through technical and economic feasibility studies, product development and the creation of prototypes, to large-scale production, including post-processing. The aim is to exploit the advantages of additive manufacturing in a component-specific manner through the optimal use of state-of-the-art technologies and comprehensive know-how, so that innovative parts are created in significantly shorter development and time-to-market periods.