AR brings the worker back into the equation

AR brings the worker back into the equation

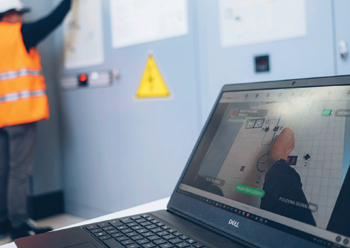

After a tumultuous 2020, the need for digitisation and keeping workers connected became crystal clear for many. This is true in all industries, but especially for industrial markets where workflow complexity, knowledge retention and share, and the financial impact from downtime and other inefficiencies are particularly severe.

According to ABI Research, the industrial market will quicken its adoption of Augmented Reality (AR) smart glasses and mobile devices to enable workers in any location and minimise costly inefficiencies. This increasing adoption will generate an industrial AR market value of $70 billion by 2025, it predicts.

“Covid-19 did not create the need for digitisation, but it certainly accelerated it,” says Eric Abbruzzese, Augmented and Virtual Reality Research Director at ABI Research. “As a high-value element of digitisation, augmented reality adds a visual element to a data-heavy system that can sometimes devalue the human worker. AR brings the worker back into the equation and creates a synergistic relationship between worker and IT/OT systems.”

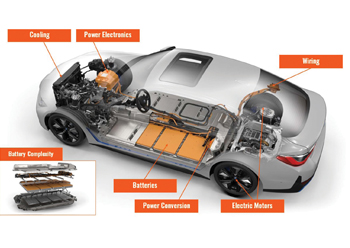

That synergy is responsible for the impressive growth rate of AR in industrial. ABI Research estimates over 15 million smart glasses devices will be used in industrial workflows found in manufacturing, transportation/automotive, AEC, energy & utilities, and logistics. Companies like Atheer, Librestream, PTC, ScopeAR, and Teamviewer leverage platform strengths across AR and industrial to integrate and deliver high-value applications like remote assistance, training, and knowledge capture. While much AR usage today is on mobile devices, smart glasses play a pivotal role in industrial where hands-free data access can be a requirement.