The VEGAPULS 6X a radar sensor to measure both liquids and solids

The VEGAPULS 6X a radar sensor to measure both liquids and solids

Level sensors help users monitor their industrial processes. Today they routinely make processes more controllable and efficient. Radar sensors joined the level measurement family over three decades age, and have spread to all corners of automation field since.

THE EVOLUTION

VEGA Grieshaber, at its base in Black Forest, Germany, has been at the forefront of Radar level sensors development. Starting from creating the first device of its kind back in 1991, to reaching over one million installed Radar sensors worldwide in 2022.

|

|

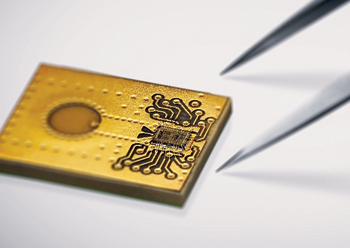

The Chip of the New generation Radar combines the experience of 1 million sensors already installed |

The technology has gone a long way. The Radar level sensors started as exclusive, expensive, complex devices applied in difficult industrial processes. And today they have become a mass-use type of devices, present in numerous places surrounding us in daily life. A person walking on a town street may not be aware that a Radar level sensor is continuously monitoring the stormwater network below his feet, enhancing quality of life. Another Radar sensor is checking on the drinking water supply reservoir, unheeded by the people using tap water in their homes. These devices are descendants of the first Radars used at refineries, offshore platforms, chemical plants and other very ‘industrial’ sites.

The technology continues to evolve. Today VEGA brings the new device that encompasses decades of development and application experience – VEGAPULS 6X. What are the novelties that make a difference in modern day technological landscape? The leitmotif is universality. There are two overarching elements to it, and we will talk about these briefly below.

THE EXPERIENCE

Radar sensors are used in a wide variety of applications. A sensor used on an oil tank requires different parameters from a sensor used in a water pipe. And even more different from a sensor used at a concrete batching plant, or on a grain silo. So, we need different devices for the different applications. Or do we?

The difference in parameters manifests itself in either hardware of the device, or in the firmware of the device electronics. VEGA, with extensive experience of complete manufacture cycle for all Radar elements, has decided to tackle these difference. Core advantage of the new VEGAPULS 6X is the new chip, designed and manufactured at VEGA headquarters in Schiltach. The chip is the heart of the Radar sensor. It defines the frequency band (C-band, K-band, W-band), the bandwidth, the dynamic range, measuring distance, energy consumption, reliability of the device.

The new 2nd generation chip used in VEGAPULS 6X enables a wide range of parameters to be available in the single sensor. The three major frequency bands, with 80 GHz leading the way in absolute majority of applications. Flexible FMCW bandwidth from 2 to 8 GHz adjusted for the measuring range limit, allowing differentiation of very near echoes, thus covering the most complex process elements. Very high dynamic range, allowing detection of small objects, or levels of liquids and solids with very low dielectric constant. Measuring distance up to 120m, adjustable on the device with ease.

The electronics logic encompasses three decades of development, and allows operation of any mode, parameters combination. Which reflect virtually any process conditions.

The result is a device that is truly universal. One device for diesel tank, cement silo, polypropylene granules, or chemical reaction vessel. The need to select appropriate model that will only work in certain location is going to be left in the past. It is time when isolated experience in many field is combined in one place, or rather in one Radar level sensor.

THE INNOVATION

The technological base is impressive. However, it is not really visible to real people, users, engineers, procurement officers, maintenance personnel. What is very visible is that life becomes much easier with this new approach.

So far the Radar level sensors, even though they are basically easy to use, were giving quite a challenge in selecting the right model for a given application. All companies involved, from manufacturers with their sales teams, to distributors, from EPCs to end-users, had to invest substantially in the product range knowledge of their staff. The VEGAPULS 6X makes all processes, from procurement, to commissioning and operation, much easier.

To identify the preferred device the person does not need to scan the product range, and compare individual models. Instead, the process details are entered into the single device configurator, and the outcome is one and the same device, VEGAPULS 6X, with the parameters according to the process details provided. Instead of learning which device works best with which DK value, which one is fit for high pressure or temperature, which wone was solids and which for liquids. Describe the process in a few mouse clicks instead. No need to dive into the manufacturers catalogue for hours. In the operation management, consider a situation when an urgent replacement is required for a level sensor of a liquid reagent tank. Ordering a new one is not an option due to lead time, budget, or any other reason. At the same time there is a final product silo, that is currently out of operation, and has the Radar installed on it. Bingo! Move the same device to the other location, address the situation, and take your time to work out long-term solution. Similar approach works for spare parts. The electronics module replacement can be done between sensors with different parameters.

Imagine ordering a device that is interchangeable between a diesel tank, a cement silo, and a water pump room. With a single set of spare parts. And best in class performance. It is the VEGAPULS 6X.

.jpg)