Graphene pellets

Graphene pellets

Nanotechnology company Gerdau Graphene has created graphene-enhanced plastics, which the company claims are stronger, perform better, and cost less to manufacture than traditional plastics. The new materials also produce significantly less waste across the value chain, it said.

The company developed the next-generation graphene-enhanced plastics at a Brazilian government-funded advanced material centre in São Paulo. The masterbatches for polyethylene (PP) and polypropylene (PE) were created in partnership with Brazil’s EMBRAPII SENAI/SP Advanced Materials Unit, and will apparently be piloted in a series of industrial applications within Gerdau’s factories.

“By adding specialised graphene additives to thermoplastic recipes, plastic producers can create stronger, more durable plastic products at a fraction of the cost and with far less petroleum and fewer raw materials needed,” said Alexandre Côrrea, CEO of Gerdau Graphene.

“Because less plastic is needed for final products, less plastic becomes post-consumer waste. There are also downstream effects, including reductions in manufacturing waste, energy consumption, transportation, and more. And, circularly, plastics can be recycled into graphene and then reused,” he added.

|

|

Graphene additives |

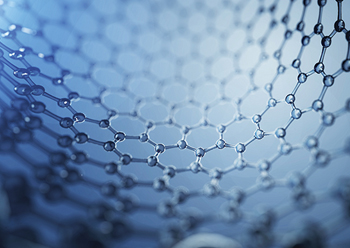

According to Gerdau, graphene – a one to ten atom-thick sheet of densely-compacted carbon that can be modified for various uses, including industrial materials – is considered to be one of the strongest materials on Earth. First discovered in 2004, with its inventors later winning the Noble Prize in chemistry, graphene’s chemical, physical, electrical, thermal, and mechanical properties are apparently in high demand.

Gerdau explained that graphene can be mixed with plastics to strengthen the plastic matrix, making the combined plastic material much stronger. The company adds that graphene can increase barrier properties against liquids and gasses, enhance protection from weathering, oxidation, and UV light, and improve electrical and thermal conductivity. Recent research also suggests graphene provides good antimicrobial properties and is recyclable.

Gerdau Graphene is aiming to develop graphene additives for virgin resins as well as post-industrial and post-consumer recycled plastics and polymers, including PP, PE, polystyrene (PS), polycarbonate (PC), PVC, and more.

The company claims graphene-enhanced plastics have the potential to reduce raw material usage by as much as 30 per cent. With 8 million tonnes of PP and 23 million tonnes of PE produced in the US annually, Gerdau said that reducing the amount of raw PP and PE needed to create final plastic products by 30 per cent could save as much as 9.3 million tonnes from being created and discarded.

“Gerdau Graphene and SENAI are involved in this project to leverage the use of graphene in Brazilian industry, increasing its level of competitiveness in the face of opportunities arising from this global macrotrend,” added Gustavo Spina Gaudencio de Almeida, Technology Coordinator at Instituto SENAI Innovation in Advanced Materials and Nanocomposites.

“The partnership signed at the end of 2021 provides a great opportunity to develop new materials, specifically masterbatches for use in polymers of great industrial application, highlighting the relevance of graphene to the market.”

In 2020, the UK-based company, Toraphene, unveiled a new material that combines biopolymers that apparently compost and biodegrade without intervention with graphene. The company claims that the Toraphene material is stronger, thinner, and less permeable than alternatives due to the addition of graphene.