Oliver Kossanyi

Oliver Kossanyi

Over the past two years, the flexible packaging industry has been actively pursuing more sustainable packaging solutions. Industry leaders are pledging that by 2025, all produced packaging materials should be recyclable or reusable. There are many ways to achieve this ambitious goal. One is to replace multi-material combinations by a mono-material such as polyethylene terephthalate (PET). For PET, but also for a broad variety of other substrates like poly styrene (PS), polyethylene (PE) or poly propylene (PP),

|

|

Illustration 1: Schematic structure of single cup yogurt and lid |

Evonik Operations GmbH says its broad range of DEGACRYL HS heat seal binders ensure a safe and secured sealing between the substrate and the lidding material. A specific application example is the packaging structure of a yogurt: the lidding material is typically made of aluminum or PET, while the cup consists of PP (especially single cups) or PS (multi cups), as depicted in illustration 1.

DEGACRYL HS heat seal binders are applied in between cup and lid, and ensure a secure sealing of the cup throughout the whole value chain: directly after the filling process, the cup is sealed and can be shipped and stored safely in local retail stores. “After purchasing, consumers can enjoy an even and smooth peeling experience when removing the lid – without a so called “slip stick” effect or presence of any strings,” said Oliver Kossanyi, Global Marketing Manager Specialty, Acrylics, Evonik.

Additionally, the coating weight of a heat seal lacquer for dairy packaging is significantly lower compared to other technologies. Sufficient heat seal strength can already be achieved at 2.5 grams per sq m (depending on the application), posing the by far the thinnest sealing method, thereby contributing to sustainable packaging solutions. Furthermore, DEGACRYL HS heat seal binders offer advantages in the application process: a final heat seal lacquer can be readily applied via standard equipment for flexible packaging converters such as roto-gravure or semi-flexo rollers.

COPING WITH ME CLIMATE

|

|

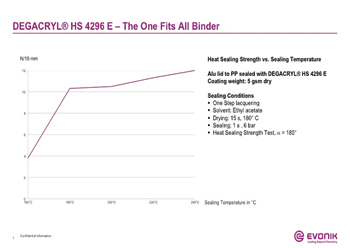

Illustration 2: Heat Sealing Curve of DEGACRYL HS 4296 E for Aluminum on PP |

DEGACRYL HS heat seal binders are applied in numerous additional packaging solutions beyond dairy. Especially in the Middle East, consumers have a preference to drink water out of water-cups. Also here, the lidding which is usually made of aluminum or PET can be easily and smoothly removed prior to consumption without spilling.

Evonik recently launched DEGACRYL HS 4296 E – a universal heat seal binder which seals against polar and non-polar substrates. The innovative binder is very well suited for water-cup packaging: compared to other liquid coating solutions, DEGACRYL HS 4296 E can be applied in a single step coating process, without addition of a primer or adhesion promoter, thus simplifying the overall production process. A straightforward dilution by adding solvents is sufficient to formulate the product, and with a blocking temperature of around 65-degC, anti-blocking agents are obsolete. According to Kossanyi, DEGACRYL HS 4296 E can even cope with the demanding climate conditions in the Middle East: high humidity and high temperatures have no influence on film rolls lacquered with the new solution. A typical sealing curve of DEGACRYL HS 4296 E is shown in illustration 2.

MONO MATERIAL PACKAGING

|

|

Illustration 3: Plain PET-film, 36μm, 5 g/sq m coated with standard heat seal lacquer |

For flexible packaging, DEGACRYL HS 4322 E is a well-established product with particular benefits in transparent packaging applications. This solution exhibits direct adhesion to PET, thus alleviating the need to apply a primer. Therefore, it is suitable for mono PET packaging like PET film sealed against PET trays. Those types of mono packaging are fully recyclable, hence contributing to waste-reduction and enabling a cleaner environment. PET mono packaging, therefore, represents a cost-effective alternative to the existing standard PET-PE composites with improved recyclability and unimpaired performance. A low haze value of less than 6 (delta haze, comparing pure PET film against coated PET film with heat seal lacquer) ensures a crystal-clear view on the packaged goods, as demonstrated in illustration 3 and 4.

Illustration 3 depicts a standard heat seal lacquered PET lid where the packaged goods are less visible due to the inherent haze of the lacquer which usually has a rather white appearance. Illustration 4 however shows a heat seal lacquer comprising DEGACRYL HS 4322 E which enables a clear view on the packaged food items due to its stand-alone low haze properties. Thereby, the transparent lidding material sealed with DEGACRYL HS 4322 E allows consumers to enjoy a high level of comfort when selecting delicate goods such as fresh fruit through a clear view on product appearance and quality.

NEW PRODUCT DEVELOPMENT

|

|

Illustration 4: PET-film, 36μm, 5 g/sq m coated with heat seal lacquer based on DEGACRYL HS 4322 E |

Both DEGACRYL HS 4296 E and DEGACRYL HS 4322 E are solvent-based heat seal binders. Process viscosity can be easily adjusted by addition of solvents like ethyl acetate (EA); during the application process, solvents evaporate and the heat seal layer is formed on the substrate. Besides solvent-based technology, Evonik is also pursuing the development of water-based heat seal binders. DEGACRYL HS 4241 D is the latest addition to the portfolio and serves specific applications which cannot be addressed by solvent-based solutions.

“The new water-based product is in particular suitable for applications such as chocolate wrapping or cheese packaging, which both demand low coating temperatures of around 70 to 80-degC, albeit do not require a high heat seal strength. DEGACRYL HS 4241 D especially stands out in this application through its superior corrosion resistance, which is needed for the protection of thin aluminum foil,” Kossanyi said.

With regards to sustainability, paper is in focus as a new substrate when redesigning flexible packaging solutions. There are numerous different paper types and qualities available, serving different needs and requirements. Recent lab results suggest that DEGACRYL HS improves basic barrier properties when coated on paper (for example water barrier and grease barrier) while at the same time enabling sealability against itself or other substrates.

Therefore, DEGACRYL HS coated paper becomes the material of choice for a broad range of packaging applications and is gradually replacing established and less environmentally friendly multi-material solutions. Moreover, the additional functionality and sealability can be achieved both via solvent-based DEGACRYL HS heat seal binders and water-based DEGACRYL HS grades, like the aforementioned new DEGACRYL HS 4241 D.

Overall, Kossanyi says its DEGACRYL HS product range contributes to sustainable packaging solutions and is the material of choice for a secured seal and smooth peel effect. Also, all DEGACRYL HS heat seal binders fulfill the international requirements for direct food contact applications, he added.