Alto Jahuel Substation

Alto Jahuel Substation

With almost 10,000 km of lines and more than 60 substations, from the Arica y Parinacota Region to the Los Lagos Region, Transelec is the main supplier of high voltage systems in Chile, South America.

Among its various substations, the Alto Jahuel substation stands out as one with the largest capacity in the country’s National Electric System, with an installed capacity of 2,554 mega-Volt-amp (MVA). It also has yards with all the voltage levels that exist in the Chilean transmission system: 500kV, 220kV, 154kV, 110kV, 60kV and 13.2kV.

|

|

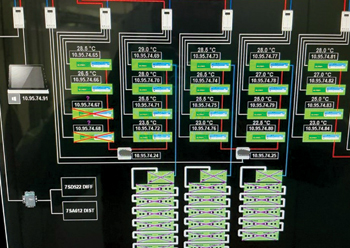

View of HMI communications |

ELECTRICAL SCADA PROJECT

To implement a supervisory control and data acquisition (Scada) system at the Alto Jahuel substation, Transelec selected Scadatech, which is considered a specialist in the development and implementation of Scada systems.

As part of its comprehensive engineering solutions for electrical power systems, the company selected the platform of PcVue Solutions for the automation of the Alto Jahuel substation, allowing the monitoring and control of its seven yards.

Initially, Transelec did not have local human-machine interfaces (HMIs) to monitor the yards from the control rooms associated with each of them, so the operations had to be performed directly on the control equipment. Due to this, Scadatech proposed PcVue’s Scada solution to provide a scalable and multifunctional platform that would allow the integration of future requirements and reduce the risk for operators when executing maneuvers by transferring operations to the control rooms of each power yard.

Technically, the application allows direct integration in MMS protocol standard 61850, in addition to the DNP 3.0 protocol, which was chosen as the basis for the project, as well as the use of existing adaptable programming within the PcVue platform. It provides the flexibility to display the dynamic coloration of the voltage levels in the substation’s single-line diagrams according to the standard used by Transelec, in which different types of alarms are indicated according to the aforementioned coloration.

|

|

NTXU57 cards |

Likewise, the HMI stations allow the visualisation in real time of status and measurements of the electrical system. It also carries out the remote control or operation towards the IED field equipment, having total control and supervision of the existing electrical system. For the control and supervision of the different displays: general unilinear, alarms and events panel, communications diagram and other areas, a menu was configured on the right side of the screen that facilitates navigation between the different areas, allowing the operator to execute his tasks locally.

Within this supervision project, the DNP 3.0 and MMS under the IEC 61850 standard protocols were used and touch screens were placed in each of the yards, which allow the deployment of the applications built in the PcVue software. The application collects data from NTX-U57 equipment used for the retrofit of the TELEGYR RTUs, which allows sending the RTU database in DNP 3.0 protocol to each of the associated displays.

As an architecture, a star connection was chosen, where the displays have an independent connection per yard, which has the advantage of not depending on the fibre optic links to the substation server room to collect data, but they work as stand-alone equipment within each yard. Among the equipment integrated into the local HMIs are GE D25 bay controllers, protections (ABB-Siemens-General Electric, MICOM), Cisco communication switches and Schneider Electric ION meters. One of the great benefits of PcVue is that it is a multi-brand platform and easily adapts to equipment from any manufacturer.

Scadatech, the company integrating this project, stated that they chose PcVue Solutions’ proposal because it has native support for various electrical protocols. This feature considerably increases the availability of the system, eliminating points of failure and reducing development time, since it is not necessary to configure different applications and interfaces, as it is generally done in the integration of communication protocols in the electrical sector. Among other elements, the PcVue platform has the highest quality standards within a highly competitive price, which made it easier for Scadatech to be favoured in the bidding process.

|

|

General one-line diagram on Touch Screen |

For Transelec, the commitment to the operational excellence of the electric transmission system and mainly the safety of collaborators and contractors of the company was a priority and PcVue has important elements to guarantee the computer security. The project has increased the security level for the operators and enhanced telecontrol for all the voltage yards.

Scadatech is currently developing an application with PcVue to extend local control to general monitoring of the entire substation from a centralised Scada in Alto Jahuel, which will allow operators to make control decisions in the event of failure of Transelec’s main Scada. The application has a general display of the substation, in three total screens, including the seven voltage yards, local monitoring of the networks through SNMP protocol, monitoring of all control equipment associated with the system (temperature and status of each of the more than 90 NTXU57 cards installed between all voltage yards) and general status of communications between the substation Gateway and the voltage yards.

IEC-60870-5-104 is being used as the communication protocol, since the monitoring is carried out with the same existing databases in Transelec’s centralised Scada, which will also allow verifying the correct operation of the communications within the system.

In fact, Transelec, together with its systems integrator Scadatech, continue to bet on the reliability provided by the PcVue software for the electrical control and monitoring of the Alto Jahuel substation. Given its capacity to adapt to different ranges of computer architectures and the ease with which PcVue provides data analysis and, therefore, quick decision-making for the operators, the platform was expanded to other corners of the company.

PROJECT HIGHLIGHTS

The challenges

• The largest capacity in the National Electric System with an installed capacity of 2,554 MVA

• 7 yards with all the voltage levels that exist in the Chilean transmission system: 500kV, 220kV, 154kV, 110kV, 60kV and 13.2kV

• No local HMIs to monitor the yards from the control rooms associated with each of them, so the operations were performed directly on the control equipment

THE BENEFITS

• Scalable and multifunctional platform allowing the integration of future requirements

• Reduce the risk of operators

• Direct integration in MMS protocol standard 61850, in addition to DNP 3.0 protocol

• Visualisation in real time of status and measurements of the electrical system

• Remote control of the IED field equipment and existing electrical system

• Displays with independent connection per yard, working as stand-alone equipment

• Guarantee of computer security for operational continuity and safety of collaborators and contractors

• High system availability

• Quick decision-making for operators

.jpg)